Valve Knowledge summary

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2022-05-27 16:06

- Views:

Valve Knowledge summary

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2022-05-27 16:06

- Views:

Valves are divided into gate valves, butterfly valves, globe valves, low pressure valves, high pressure valves, safety valves, pressure relief valves, filters, anti-corrosion valves, check valves, pressure reducing valves, ceramic valves, overflow valves, high temperature valves, low temperature valves, etc.

I. Classification

By power

Automatic valves: valves that rely on the medium's own force for action. Such as check valves, pressure reducing valves, traps, safety valves, etc.

Driven valve: rely on human power, electricity, hydraulic, pneumatic and other external forces to manipulate the valve. Such as globe valves, throttle valves, gate valves, disc valves, ball valves, plug valves, etc.

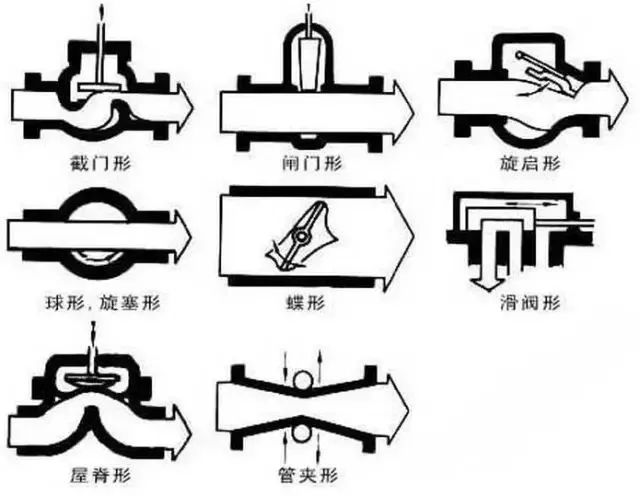

By structural characteristics

According to the use of

Open valve: cut off or connect the pipeline media. Such as up to the valve, gate valve, ball valve, plug valve, etc..

Control valve: adjust the pressure or flow of the medium. Such as pressure reducing valves, regulating valves.

Check valve: to prevent the backflow of media. Such as check valves.

Distribution valve: change the flow direction of the medium, play a distributive role. Such as three-way plug, three-way stop valve, etc.

Safety valve: the pressure exceeds the limit value, the discharge of excess media to ensure the safety of equipment. Such as safety valves, accident valves.

Gas drain valve: retain gas, remove condensate, such as traps.

Open valve: cut off or connect the pipeline media. Such as up to the valve, gate valve, ball valve, plug valve, etc..

Control valve: adjust the pressure or flow of the medium. Such as pressure reducing valves, regulating valves.

Check valve: to prevent the backflow of media. Such as check valves.

Distribution valve: change the flow direction of the medium, play a distributive role. Such as three-way plug, three-way stop valve, etc.

Safety valve: the pressure exceeds the limit value, the discharge of excess media to ensure the safety of equipment. Such as safety valves, accident valves.

Gas blocking and draining valve: retain gas, remove condensate, such as traps.

According to the method of operation

Manual valves: with the help of handwheels, handles, levers, sprockets, gears, worm gears, etc., by human to manipulate the valve.

Electric valves: Valves operated by electricity.

Pneumatic valves: valves operated with the help of compressed air.

Hydraulic valves: valves operated by external force with the help of water, oil and other liquids.

By pressure

Vacuum:Valves with an absolute pressure less than 1 kg/cm2.

Low pressure: valves with a nominal pressure of less than 16 kg/cm2.

Medium pressure: valves with a nominal pressure of 25-64 kg/cm2

High pressure: Valves with a nominal pressure of 100-800 kg/cm2.

Ultra-high: valves with nominal pressure of 1000 kg/cm2 or more

Divided by medium temperature

Ordinary valves: -40 to 450 ℃ (medium temperature)} of the valve.

High temperature valve: 450 to 600 ℃ (medium temperature) of the valve.

Heat-resistant valves: 600 ℃ or more (medium temperature) of the valve.

Low temperature valve: -40 to -70 ℃ (medium temperature) of the valve.

Deep cold valve: -70 to -196 ℃ (medium temperature) of the valve.

Ultra-low temperature valve: -196 ℃ below (medium temperature) of the valve.

According to the nominal diameter points

Small bore: nominal diameter of less than 40 mm valve.

Medium bore: nominal diameter 50 to 300 mm valve.

Large diameter: nominal diameter 350 to 1200 mm valve.

Extra-large bore: valves with a nominal diameter greater than 1400 mm.

The above classification is not absolute, can be classified from other angles, just master these basic classification, to understand the wide range of valves or a great benefit.

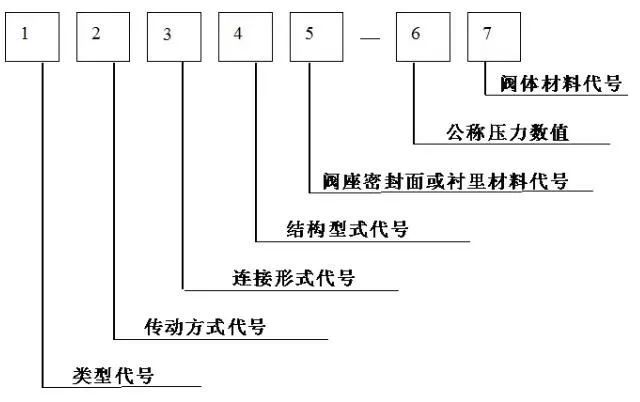

Second, the model

In accordance with the provisions of the "Valve Modeling Method", the valve model is divided into seven units.

Note: The fifth and sixth units are connected by a horizontal bar.

The first unit is the type code, expressed in pinyin.

For low-temperature valves used below -40 ℃, with heating jacket material insulation valves and valves with bellows (instead of stuffing box), in front of the type code, respectively, add the letters D, B and W in Hanyu Pinyin.

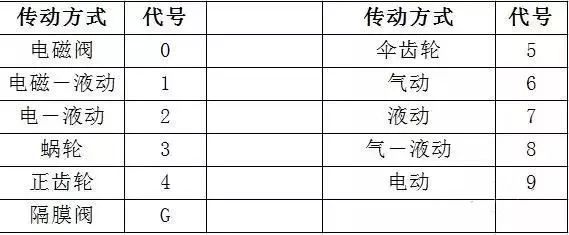

The second unit is the transmission mode code, expressed in Arabic numerals.

Pneumatic or hydraulic valves, usually divided into normally open and normally closed, normally open with 6K, 7K, normally closed with 6B, 7B.

The third unit is the connection form code, expressed in Arabic numerals.

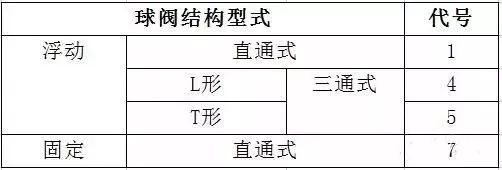

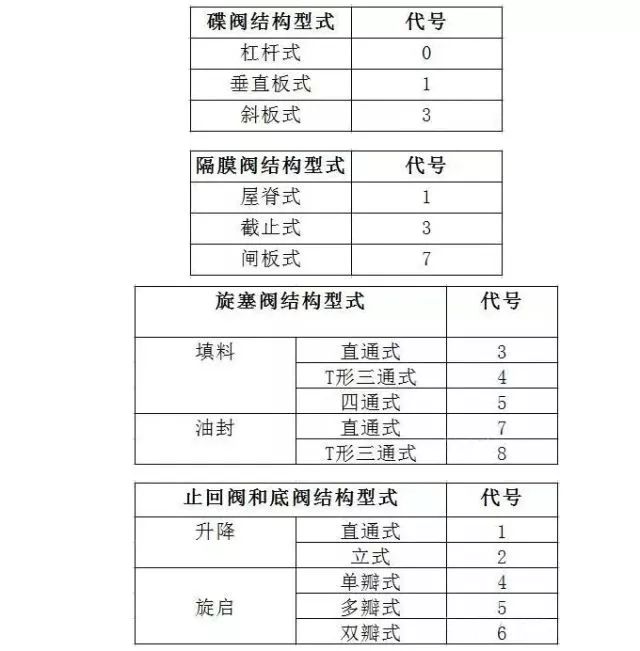

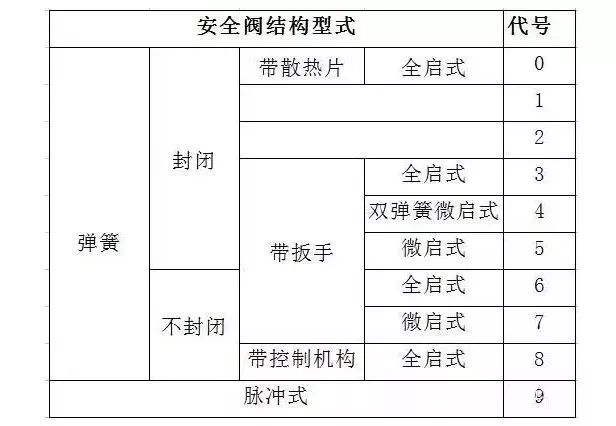

The fourth unit is the structural model code, expressed in Arabic numerals.

Lever type safety valve, add the G word before the type code, digital code, the new standard does not provide. Old standard: 1 single lever micro-open type, 2 single lever fully open type, 3 double lever micro-open type, 4 double lever fully open type, 6 pulse type.

The fifth unit for the valve seat sealing surface or lining material code, with the hanyu pinyin letters

When the sealing surface is machined directly on the valve body, it is denoted by W.

Unit 6: Indicates the nominal pressure value.

The so-called nominal pressure refers to the pressure that the valve is nominally subjected to. The actual pressure-bearing capacity is larger. For safety reasons, control within the nominal pressure. According to JB74-59 standard, the nominal pressure value is expressed as follows: 1, 1.5, 4, 6, 10, 16, 25, 40, 64, 100, 200, 250, 320, 400, 500, 640, 800, 1000. 1000 or more is not specified.

Finally, the seventh unit, using the hanyu pinyin alphabet to indicate the valve body material.

But the nominal pressure kg/cm2 of gray cast iron valve body and kg/cm2 of carbon steel valve body, this code can be omitted.

The above classification shows that there are a wide variety of valves; so many categories, there must be a unified model preparation method, in order to allow the purchase of users through the nameplate will be able to know a certain valve structure, characteristics and materials.

Three, marking

01 valve identification role:

Valve identification in the absence of valve drawing information, lost nameplate and valve parts are not complete, the correct use of the valve, welding valve parts, repair valve parts and replacement valve parts is of great significance. Now the valve identification, material identification and valve identification is divided as follows.

The use of "valve station basics" learned knowledge, according to the valve nameplate and logo and the color of the paint on the valve. You can directly identify the valve category, structural form, material, nominal diameter, nominal pressure (or working pressure), adaptable media, temperature and closing direction.

1. The nameplate is fixed on the valve body or handwheel. The data on the nameplate is relatively complete and reflects the basic characteristics of the valve. According to the production plant on the nameplate, ask the raw well factory for drawings and information about the valve's vulnerable thump, and refer to the repair according to the factory date. According to the use conditions provided on the nameplate, determine the material and form of replacement gaskets, packing and determine the material of replacement of other valve parts

2. The sign is marked with casting, printing and other methods on the valve body to indicate the nominal pressure, working pressure, nominal bore and media flow direction of the valve.

There is also a sign on the valve - openness indicator, which has an open ruler scale or indicates the open and closed arrow, etc. Throttle valve, concealed stem gate valve is installed on the upper end of the opening indicator, marked on the handwheel with an arrow pointing to indicate the direction of closure. In the valve stem end part engraved with a straight groove mouth and valve channel in line with the opening, the groove and channel into 90 ° for closed.

3. The valves are coated with various paints, not only for rust prevention and good looks. Rather, it is to facilitate the identification of the valve material. Paint indicating the material of the valve body. Paint indicating the material of the sealing surface.

In order to see its structure, material and basic characteristics from the appearance of the valve, the requirements of the valve body casting, printing or placement on the nameplate, indicating the valve model, nominal diameter, media flow and factory name, and in the valve body, handwheel and flange on the outer edge of the specified brush different colors of paint.

In accordance with the JB106-59 a Ministry of Machinery standards, indicating that the valve body material paint should be brushed on the outer surface of the valve body is not processed, its color and the relationship between the valve body material is as follows.

However, acid-resistant steel or stainless steel valve body, can also be unpainted. Non-ferrous metal valve body, no need to paint.

Paint indicating the sealing surface material, brush on the handwheel, handle or cover of the automatic valve parts, the color of which is related to the sealing surface material as follows.

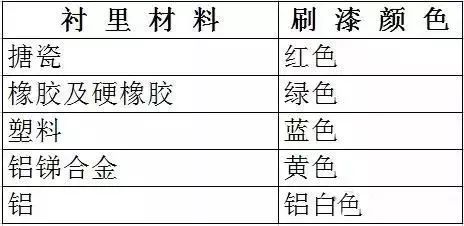

Valves with lining shall be painted with supplementary identification paint on the outer surface of the connecting flange in the following colors.

02 Examples of meanings on valves.

The meaning of DN on the valve

DN: refers to the nominal diameter of the valve, generally followed by a number, such as nominal diameter 250mm, should be marked DN250. usually, the valve channel diameter and nominal size is the same, but when the valve body using pipe welding structure or the pipeline connected to it is connected with standard steel pipe flange, the actual diameter of the valve channel is not equal to the value of the nominal size DN.

The meaning of WCB on the valve

WCB: indicates the valve body material, other parts of the valve may be other materials. wcb refers to the ASTM A216 WCB level, is a carbon steel castings (W - weldable: welding the first letter, indicating that the material welding performance is good; C - cast steel: cast steel the first letter; B - steel mechanical properties of the B grade) together is: mechanical properties of weldable cast steel parts. letter; B - mechanical properties of steel is B grade) together is: mechanical properties of B grade weldable cast steel parts. It is ordinary carbon steel, equivalent to 25 or 35 carbon steel.

The meaning of PN on the valve

PN: the nominal pressure of the valve, followed by an integer number consisting of. In China, involving nominal pressure, for clarity, usually give the unit of measurement, to "MPa" said. For example, PN100 means the nominal pressure is 10Mpa, which is 100Kgf/cm2.

Sometimes the nominal pressure is also marked in the following position.

Key points of valve marking

1. Unless otherwise specified, the valves of the American standard according to API600. API6D or MSS SP-25, the valves of the national standard according to G/T 12220 standard has a permanent logo, the logo should include the casting melting furnace number or the casting mark of the manufacturing plant.

2. The label should be firmly fixed on the obvious part of the valve, its content must be neat, correct, and should comply with the provisions of GB / T 13306, its material should be stainless steel, copper alloy and aluminum alloy manufacturing production.

3. Only when it is not feasible to apply the required markings on the valve body, the markings can be applied to the nameplate, however, to indicate the flow direction of the valve must be marked on the valve body, which is the same no matter what the standard of the valve.

4. Paint used for color coding and marking shall not contain any harmful metals or metal salts, such as zinc, lead, sulfur, copper, tin, chloride and other substances that can cause corrosion when in a hot state, and the paint shall be resistant to corrosion by salt water, tropical environments or similar conditions.

5. For small size objects that are difficult to mark, the application of stainless steel wire bolts stainless steel tagging method to mark.

6. Regarding the logo engraved on the nameplate, generally the model, material, pressure, standard, applicable temperature, use of media, production date, are indispensable. To facilitate the procurement of maintenance and replacement.

Marking method of the logo

1. When the valve body is formed by casting or die-casting method, its logo is cast or die-cast on the valve body at the same time as the valve body.

2. When the valve body shape by die-forging method, its logo in addition to the valve body at the same time die-forging or die-casting forming, can also be used in the valve body embossed method logo. When the shape of the valve body using forging processing, steel pipe or steel plate rolled and welded into shape, its logo in addition to the formation of the embossing method, but also other methods that do not affect the performance of the valve body.

Marking style of the logo

Nominal size numerical designation, pressure designation or working pressure designation, flow direction symbol, nominal size numerical designation above the pressure designation.

Marking position of the marker

1. The content of the marker, generally marked on the part of the valve body easy to watch. Marking should be marked as far as possible in the valve body vertical center line of the central control position.

2. When the content of the mark on one side of the valve body marked position is not enough, can be marked on another side of the valve body in the position of the control.

3. The mark should be obvious, clear and neatly arranged.

Marker size

1. Casting logo mark size, font and arrowhead layout, font and arrowhead size to row, should be made into a convex profile.

2. Embossed logo size, arrow size by the design drawings.

3. The font number of each product logo, also according to the size of the specific product shape by the design drawings.

Recognition of signage

The placard is usually fixed to the valve body, flange or handwheel. The data on the placard is relatively complete and reflects the basic characteristics of the valve. The placard gives different contents for various different valves.

Painting of valves

1. cast iron, carbon steel, alloy steel material valves, the outer surface needs to be painted factory, the internal and external surfaces of the valve can be used to meet the spraying process instead.

2. The painted layer should be durable, beautiful, and ensure that the logo is obvious and clear. Use can meet the use of temperature, non-toxic, non-polluting paint.

3. The paint layer of the handwheel parts should be according to the contract or enterprise standard.

4. The surface of the pressure-bearing shell of the valve made of copper alloy is not painted.

5. Acid-resistant steel, stainless steel valves are not painted on the surface of the pressure-bearing shell, if the contract requires painting, paint according to the contract requirements.

6. Valve drive device painting: manual gear transmission mechanism, the surface of the paint color, valve drive device (pneumatic, electric, hydraulic) paint color generally according to the provisions of the enterprise standard, when the user order contract requirements, according to the color specified by the user.

Products & Services

Contact Us

TEL:+86 512 67420760

E-mail: sales@valveman-service.com

ADD:108-C,No.32 Dongfu Road,SIP,Suzhou,China

Follow Us